Match The Paddle To Your Concrete Mix

For the highest quality mix, the paddle is your most important choice.

There is a definite science behind mixing. Many contractors are not aware they can save a lot of time and money by perfecting their mixing techniques. When you match the paddle to your mix, not only is it easier to use, but it can prevent errors and contribute directly to customer satisfaction.

Different materials respond in different ways. The shape of the paddle helps you mix your materials quickly and efficiently, and ultimately delivers better quality on the job.

The Problem With The Wrong Paddles

With the wrong paddle design/shape, you could face bigger problems down the road, such as:

- Costly repair work. If it’s not right, you have to fix it.

- Wasting time (longer mixing time when using the wrong paddle adds up).

- Quality of the mix suffers: clumps, air bubbles, etc.

- Extra time and repairs dig into your profit margins.

- Using the wrong paddles can result in cutting pieces out of your bucket, which destroys the bucket and ruins your mix. You don’t want that!

Understanding The Two Most Important Factors

When it comes to choosing your paddle, there are two major factors to consider.

- Mixing Volume: How much you are mixing per batch determines the diameter, or size of your mixing paddle.

- Material: The shape/design of the paddle, and the mixing direction determine optimal results of your mix.

How Different Paddles Mix Differently

Mixing Direction

There are only three ways paddles mix: Bottom-Up, Top-Down, and Side-to-Side. That’s it!

You can see how these actions mix differently in this video:

Mixing Action revealed – its in the PADDLE.

Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

Bottom-Up

The material is conveyed upwards through the middle of the mixing paddle from the bottom of the bucket and flows down the sides.

Materials that Require This Method

Thick and dry mixtures such as concrete, plaster, grout, cement, and aggregate-filled materials.

Optimal Paddles

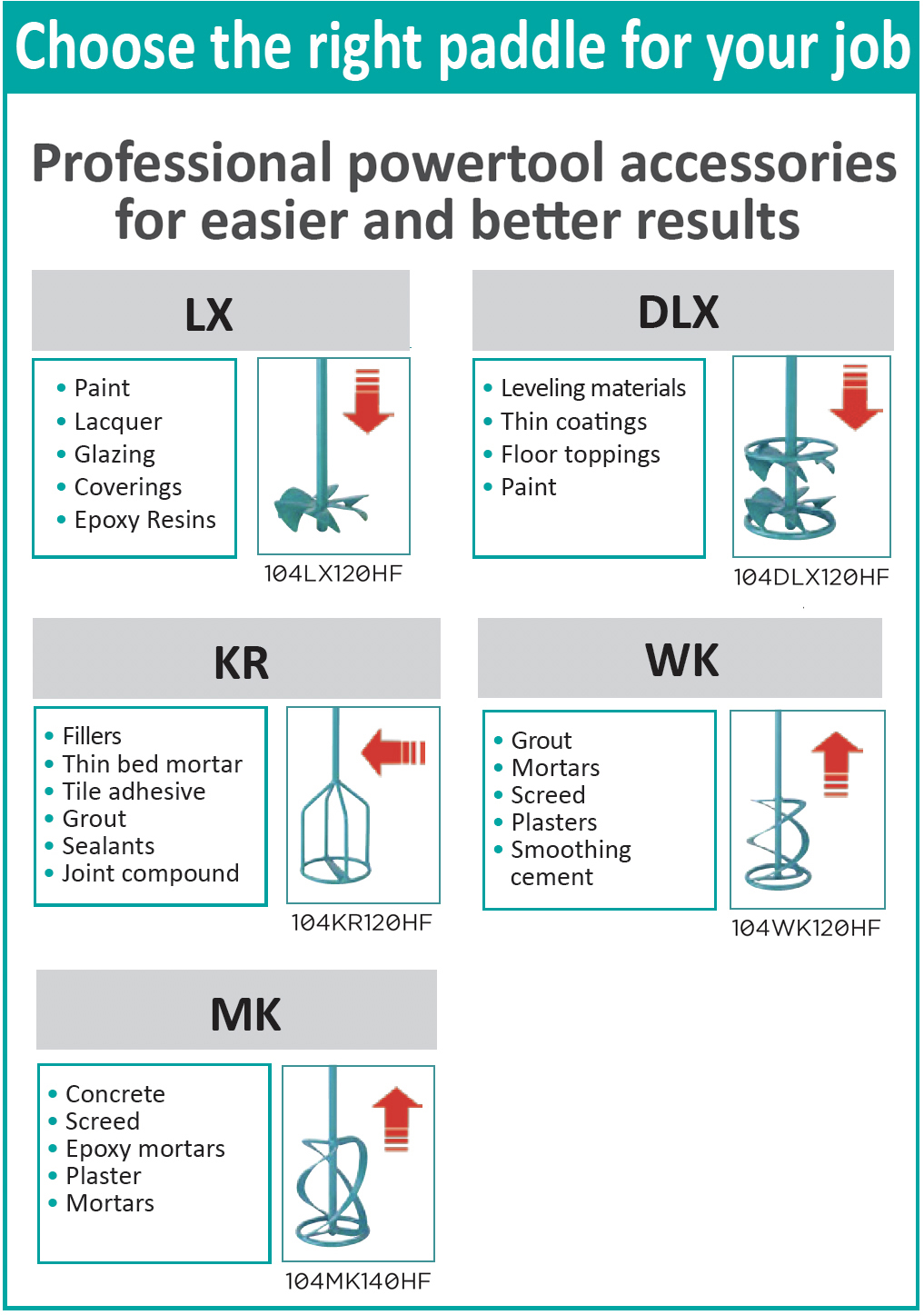

WK and MK Style Paddles

Top-Down

The material is forced down from the top and then flows back up the sides. Any clumps are broken up by the high force generated by the drive and the user, without splashing. It involves greater strain on the drive unit and user.

Materials that Require This Method

This method is ideal for thin flowable materials such as paints, epoxy, and floor leveling materials, including those that contain fibers.

Optimal Paddles

FM, LX and DLX Style Paddles

Side to Side

The material is swirled on a single plane. The components only flow up or down when the mixing tool is moved accordingly. The suction effect results in optimal mixing results, according to the consistency of the material. Less air in the material and, as a rule, higher shear forces, prevent the formation of clumps.

Materials that Require This Method

This method is ideal for powders such as thin-set, tile adhesive, and joint compound.

Optimal Paddles

KR Style Paddle

Usage Note: Always refer to the material manufacturer’s notes. Carefully check the suitability of the mixing tools for the task at hand and the notes in the operating instructions.

Mixing Guide

Save time and find out which paddle is right for the job with the Collomix Mixing-Atlas, an online guide where you can simply click on the material or category to see which paddles fit best for your job.

To sum up, investing a little time and money into the right mixing methods for your jobs can payoff in the long run and put more money in your pocket. All the mixing options mentioned above can be found in the White Cap store.