The Benefits Of Lean Construction

What Is Lean Construction?

Lean construction is a philosophy by which the construction team adopts practices and technologies that reduce costs, materials, time and effort, specific to the project at hand.

For most contractors this sort of pre-job review is very commonplace, especially as they prepare their individual bids and project-critical paths. But when adopting lean construction into the project preparation, contractors are asked to extend their planning beyond their own tasks, and include all stakeholders to determine the best approach. This approach includes the owner, engineer of record, and all other jobsite participants.

The principals involved in lean construction have been modified from the those of the better-known managerial approach of lean production, often associated with six sigma. Construction management experts formally coined the term in the 1990’s. Their studies determined that applying original “Lean Production” processes designed for a manufacturing application didn’t entirely work in the construction field – thus “Lean Construction” was conceived.

Lean Construction Key Elements

There are five common elements that comprise the lean construction philosophy. To think lean, the construction team should adopt processes that:

- Shorten Construction Time

- Reduce Costs

- Accelerate Activities

- Improve Planning

- Improve Process control

When a contractor can adopt lean principals into their operations, good things happen. The most dramatic improvement comes from greater worker utilization. In a 2007 industry study carried out by Dr. Roger Liska, from the Department of Construction Science and Management at Clemson University, the results showed that the average construction worker was operating at about 40% efficiency. The remaining loss of productivity is largely attributed to poor coordination of the construction team that caused delays in waiting for materials, equipment or information, design errors, and worker scheduling, inefficient processes or poor systems design.

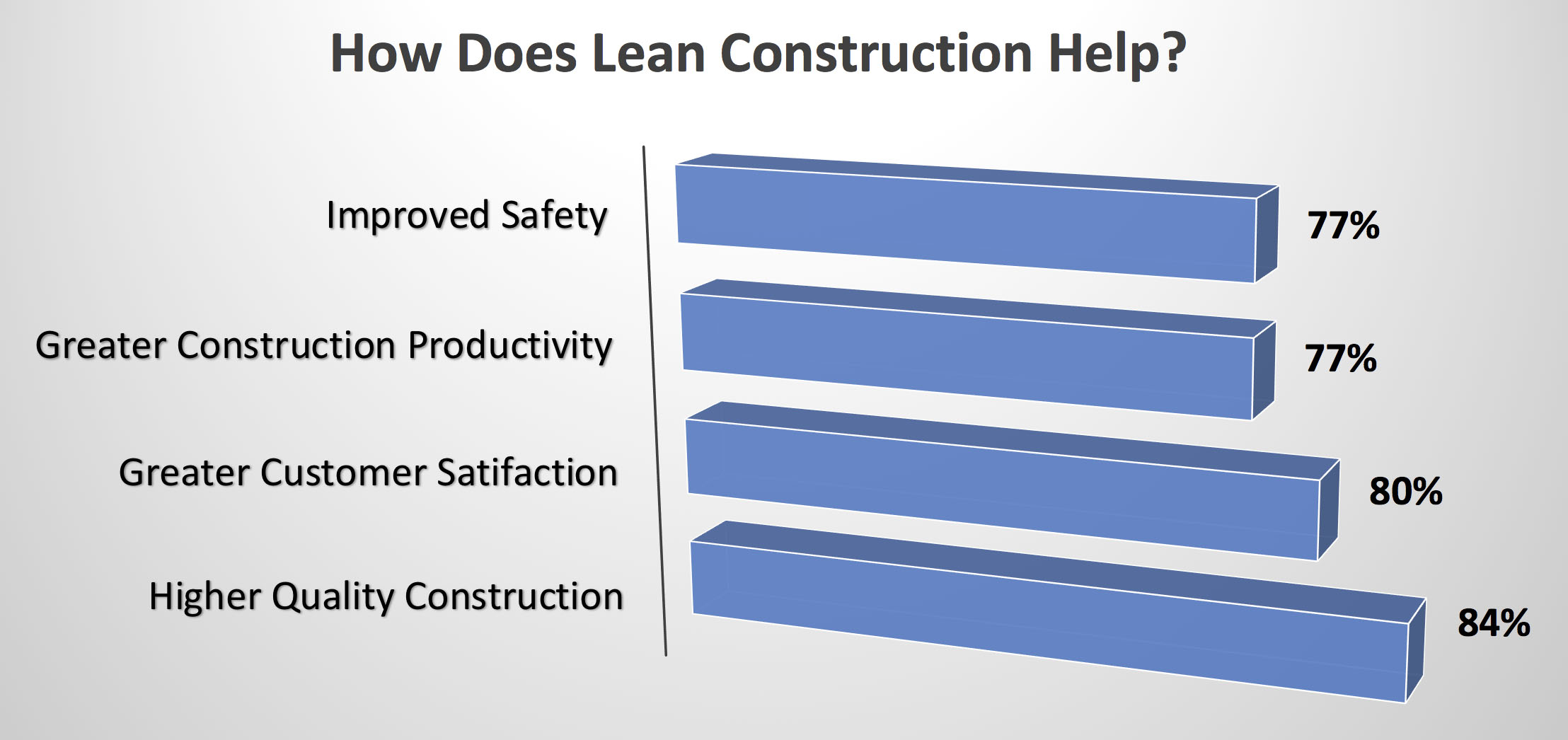

While this research may be dated, many contractors are still conducting activities as they did decades ago. But when contractors adopt lean construction principals, a 2018 survey reported these stats:

The difference between lean production and lean construction

Lean Production focuses on the decrease of time for turnover, achieved by the elimination of waste in creating a product. This philosophy was developed by the Toyota Production System after World War II.

Lean Construction focuses more on the actual construction process rather than the production of construction. This methodology was developed specifically for construction about 30 years ago.

Let’s look at a common construction task to consider how a master mason would build a brick wall using these methods.

Lean Production

Lean Production describes how to improve the process of how well masons and tenders are working together, with the final product being a wall that proceeds quickly upward. Tenders quickly adjust the mortar’s moisture so the masons can set each brick in an eye-pleasing pattern as ordered by the owner. Tenders maintain consistent supply of brick and mortar just in the mason’s reach to make each move count. on the board. When there’s a window or change of profile, the mason knows how to properly make the adjustment that complies with the drawing specification. And this coordinated process, happens all along the perimeter wall. This fine-tuned process has successfully erected walls for generations.

Lean Construction

Modifications to the traditional construction method above would first start with how the mortar is ordered, switching from jobsite mixing from piles of individual ingredients to preblended products. Telehandlers now position custom-sized cubes of brick on the work platform to minimize handling and excess material. Fixed scaffolding sections could be replaced with mobile work platforms that quickly adjust to the proper work height.

Lean Construction takes a much broader view of the entire construction process. Contractors would approach the design team to ask for consideration of processes that could reduce labor, increase productivity and decrease wastes. This is already happening on selected projects in the US. Mason contractors have already incorporated robots to place brick on walls. And there are some projects, on which mason contractors are placing post-tensioned brick panels built offsite.

Why is Lean Construction so important right now?

Contractors are facing the greatest influx of innovations in the history of construction. Traditional practices and methods that had produced profitable results on projects for generations, now are being supplanted with technologies that are reshaping the entire project process including design, bidding and construction. These innovations are broad in scope, affecting every aspect of a contractor’s activities, including iOT, drones, and Building Information Modeling (BIM) with the additional opportunity to enlarge the construction team with other contractors, owners and the engineers of record.

Along with these revolutionary influences come two other operational factors that are shaping the new normal in construction. First, owners are demanding tighter timelines for project completion, causing contractors to consider modular and offsite approaches to common jobsite tasks. And second, contractors are facing the more practical challenge of securing and retaining qualified labor.

So how can contractors adapt to construction innovation, satisfy their client’s expectations, and still be profitable? The answer is to adopt lean construction principals into their operations and organizations.

How Do I Start The Lean Construction Process?

As with all innovations, the best way to implement lean construction is to examine the common contractor’s tasks that occur routinely on each large and complex projects to identify those tasks that contain a high degree of repetition. Contractors who have undertaken this approach, often determine that 60 to 80 percent of the work on a construction project to be repetitive in nature.

The next step is to include these yard excellence tasks from all contractors into a comprehensive action along with project leaders who will monitor each task. Using the lean philosophy, when any variation of a normal task is observed, the construction team should work on ways to correct the deficiency.

Building A Stronger Future

When contractors adopt lean construction as part of their strategic plan, they are readying themselves for both the present and the future. The immediate returns will be greater efficiency, stronger return on the capital investment of new technology and equipment, and greater operating margins.

But more importantly, they will be transforming their business with which they can build better relationships with their customers. They will be building walls of successes by which they will be recognized as the go-to contractor who completes projects on time, on budget, and with high quality.

Want To Learn More About Lean Construction?

Founded in 1997, the Lean Construction Institute is a non-profit, membership-based organization with a vision to transform the built environment through Lean implementation. The Institute offers courses and conferences at which contractors can learn more about lean construction principles. www.leanconstruction.org

![]()

Check out these links for more info on Lean Construction:

https://www.constructconnect.com/blog/breaking-principles-lean-construction