Placing Concrete When The Heat Is On

How To Place Concrete In Hot Weather

When Summer is in full swing and temperatures are climbing, those of us that work with concrete materials need to adjust our workflow for hot weather pours. Experts agree that the ideal temperature for placing concrete is approximately 50˚- 60˚ Fahrenheit. Since weather is unpredictable, and often uncooperative, we need to be flexible and prepared to pour in the hot weather.

Concreting When the Mercury Rises

The American Concrete Institute (ACI) defines hot weather as:

“Any combination of high ambient temperature, high concrete temperature, low relative humidity, wind speed and solar radiation.”

These weather conditions can negatively affect the quality of concrete. ACI notes that while these issues primarily happen in summer months, high winds, low relative humidity and solar radiation can occur throughout the year. So, understanding hot weather concreting will benefit you all year round.

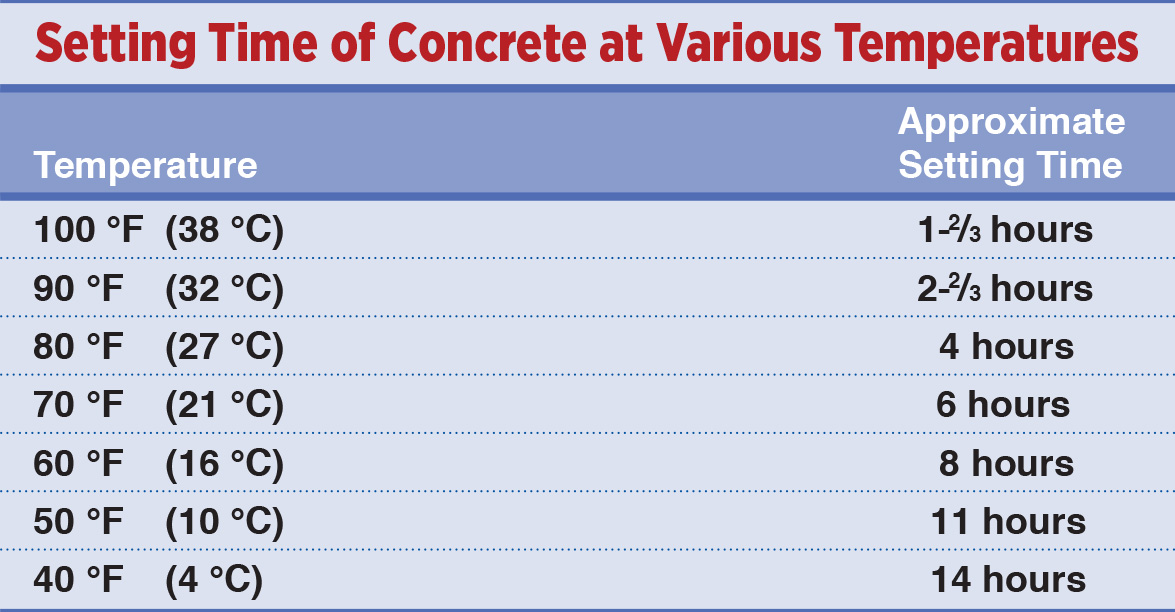

Under normal weather conditions, concrete can set in 8-48 hours, reaching 70% strength in approximately seven days. It then takes up to 28 days to fully cure and reach its full strength. Weather conditions have a profound effect on setting and curing. In colder temps, the concrete takes longer to set allowing the crystals formed within the concrete more time to strengthen. Conversely, warmer temps mean that crystals form more quickly, allowing for less time to strengthen. For example, at 100 degrees Fahrenheit, concrete could set in as little as two hours.

You’ll be able to save time and money by recognizing how hot weather affects newly poured concrete and mitigating potential problems wherever possible.

Hot Weather Effects

Hot weather conditions increase the evaporation of the surface moisture on freshly poured concrete and accelerate the setting time. Evaporation can remove the surface water from a poured slab; this surface water is needed to keep the concrete hydrated and prevent drying out. When evaporation rate is high, as it is in warm weather, this can result in surface cracking or shrinkage of plastic (contained within the concrete mixture) prior to setting. Refrain from using water to help rehydrate the surface as this will weaken the final product as it evaporates and contribute to crazing. Better to use evaporation retarders and finishing aids like Solomon Brickform’s Lythic Day 1.

Drastic changes in ambient temperature can also create thermal cracking. For example, if the concrete is poured during a hot day, which then cools quickly at night, this can cause cracking or shrinking. An increase of 20 degrees can reduce setting time by as much as 50%. Additionally, as the concrete temperature itself climbs, this also speeds up the setting process. When pouring concrete, time is of the essence in hot weather.

Potential problems with pouring concrete in higher temperatures include:

- A reduction in set time makes concrete difficult to handle – this also means reduced time to place, consolidate and finish the concrete – so the crew has to work faster

- Acceleration in slump loss – this can also lead to the loss of entrained air

- Plastic shrinkage and cracking – as moisture evaporates too quickly, the surface can crack or affect the plastic contained within the cement

- Reduction in ultimate strength – when concrete cures too quickly in the heat, strength can suffer. Concrete that is cured at a standard 70˚F temperature will be markedly stronger than a slab cured at 90˚F.

Keep a Cool Head in Hot Weather

Let’s be realistic, none of these potential hot weather problems are going to slow down your next pour regardless of the temperature. But by making some adjustments to the project methodology and the concrete composition you can have a successful outcome.

Chemical Additives

As concrete sets, it also reaches full strength quicker. However, this faster set can also mean less strength in the curing process. Concrete is all about strength, so adding chemicals to the concrete mix can help increase its ultimate strength.

Chemical additives are used to accelerate or retard the workability, consistency, durability, and strength of concrete. In the case of a hot weather pour, consider adding a set-retarding admixture. This type of additive can delay the chemical reaction that occurs in the setting process allowing more time to finish the concrete before it sets up in the heat.

Water and Ice

To maintaining cool concrete in hot weather, the temperature within the concrete can be reduced by using cool water or ice as part of the mixing water. Additionally, spraying aggregates with water can help keep the concrete cool.

Liquid Nitrogen

Water and ice used to be the most practical and cost-effective methods for cooling concrete.

These days, using liquid nitrogen (LIN) can actually be more effective and economical. Benefits of cooling with LIN include: more predictable, consistent temperatures from batch to batch and versatility (you can use it to cool your aggregates, add to the water mix, or directly on the concrete).

Just keep in mind that LIN is not always readily available, so you’ll need to check for industrial production facilities in your area.

How should you prepare for the concrete pour?

- Have concrete equipment and supplies ready to use before hot weather arrives.

- Keep subgrade and forms moist so they won’t absorb water from the mix.

- Use sunshades and windbreaks whenever possible.

- Be sure to use concrete materials that perform well in higher temperatures.

- Stay in constant contact with the ready mix concrete provider and have everything prepared before the mix truck arrives. Don’t make the truck wait on you!

Avoid scheduling concrete pours on 100 degree days. If that isn’t feasible, schedule deliveries during the coolest part of the day, early mornings or evenings, avoiding the hottest part of the day. Ensure you have a full crew so that you can get concrete placed and finished as soon as possible. Make it easy for the mixer trucks to get onsite and in position with little to no downtime.

Keep Your Crew Hydrated!

During placement don’t forget to protect your crew from the elevated heat too. Make sure they drink and have plenty of fluids available, schedule frequent breaks in shady areas and constantly be on the lookout for signs of heat stress.

Next steps after placement

After placement, the concrete should be struck off and darbyed immediately. Be sure to use evaporation retardants, fogging or misting with water – or cover with a vapor-proof sheet before screeding. This helps prevent rapid drying, crusting, plastic shrinkage and rubber sets. Temporary covers like continuously moistened burlap can be placed over the fresh concrete and removed in small sections immediately ahead of the finishers.

Is there a best way to finish a hot-weather concrete pour?

You can eliminate high-risk practices like smooth trowel finishing by substituting a burlap drag or broom finish. Curing should happen when surfaces are hard enough to resist marring and sealing should be done with a good quality sealer a minimum of 30 days after the concrete has been placed and cured.

With a little bit of planning and lots of cool water you can make a concrete pour in hot weather seamless and successful. And don’t forget the sunscreen.

![]()

Check out these links for more information on pouring concrete in hot weather check out these links:

https://www.thebalance.com/pouring-concrete-in-hot-weather-845030