Preventing Worker-To-Worker COVID-19 Transmission

Mitigating Virus Transmission Between Workers

Contractors have taken great strides in adopting procedures to safeguard workers from jobsite exposure to respirable silica. But implementing safety procedures to mitigate the transmission of the new coronavirus from worker to worker is causing contractors to re-examine normal activities.

Enhancing the use of personal protective equipment (PPE) has been recommended as an important approach for worker protection. If you’ve been following our Safety Webinar, PREVENTION is the fourth step towards creating a COVID-free work zone, along with enhanced jobsite screening, disinfecting, and work assignment procedures establishing physical distancing. (See links to the 4 steps at the end of this article.)

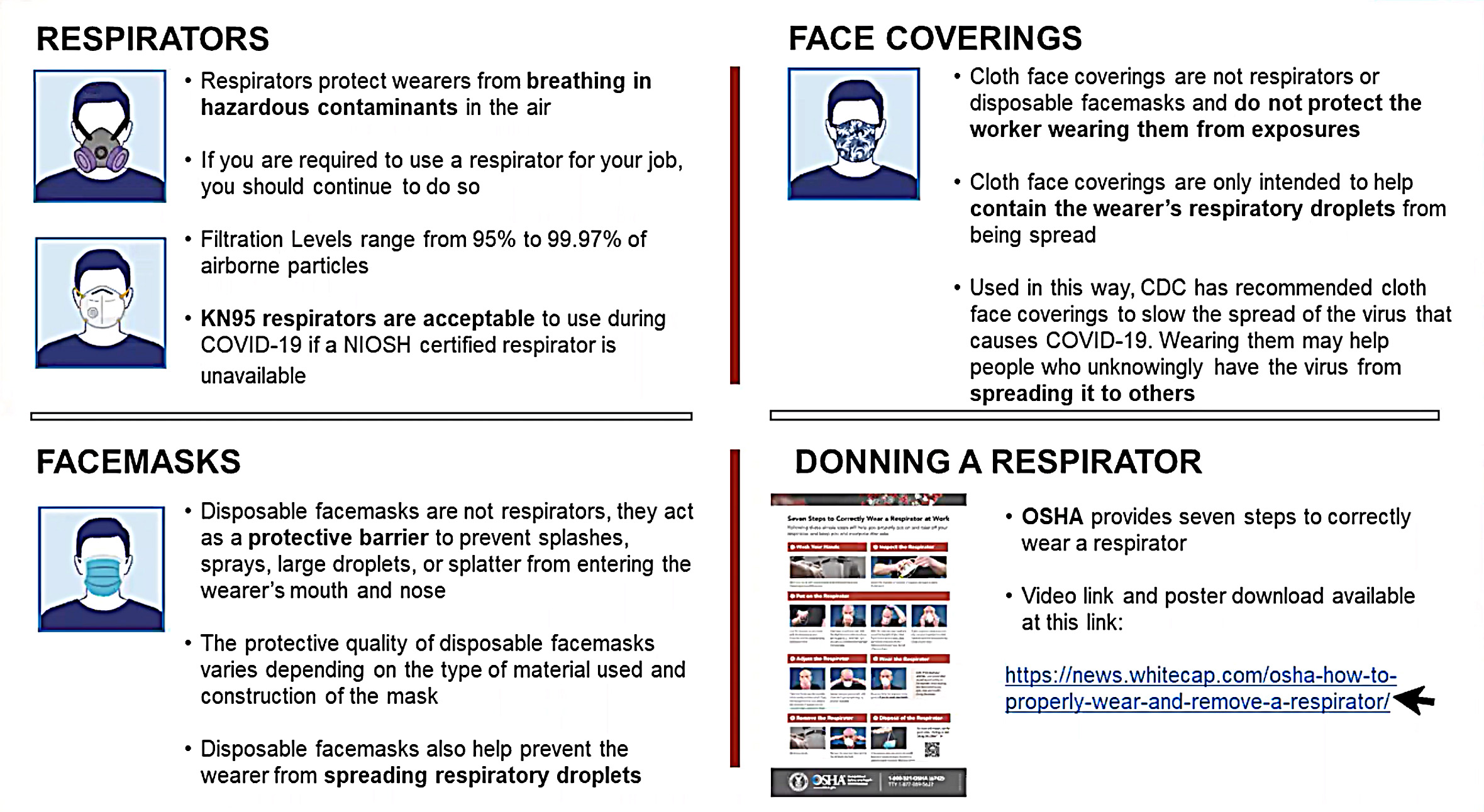

Respiratory Protection vs. Transmission Mitigation

Bruce Donato (a safety expert at K&A First Aid and Safety, Inc.) recommends contractors pay close attention to the “why” they are providing PPE. OSHA assigns most construction jobsites that follow physical distancing procedures to the low or medium risk category of infection. In these settings, contractors should focus on protecting workers from workers. Donato suggests that contractors identify these procedures, including PPE and other engineering control devices, as “Transmission Mitigation Equipment”. Then the mask becomes an engineering control that protects workers from a hazard (other workers).

It’s important to communicate this to all workers: that the reason they are wearing face masks, or face coverings is to protect their coworkers – not to protect themselves.

Required Use of Face Coverings – Managing COVID-19 in the Workplace

Safety expert Bruce Donato (K&A First Aid & Safety) discusses the practical aspects of managing COVID-19 in the workplace. White Cap Coronavirus Updates: htt…

This is much different than in construction jobs with “known hazards,” – such as silica dust, or other high exposure risk jobs like first responders, where PPE use can be categorized under OSHA’s respiratory protection standard (1926.103). In these scenarios workers need to wear specific gear for self- protection.

Donato also references the CDC reports that state nonsystematic workers can unknowingly transmit viruses when they cough, sneeze, or exhale strongly. These exertions spread the virus through droplet and aerosol to the nearby air space. Once airborne, droplets with viruses can either fall to nearby surfaces or be inhaled by others. Barriers, including face coverings, can serve to limit the spread distance.

Engineered measures, such as barriers, are important during the COVID-19 pandemic.

OSHA has asked contractors to identify and implement any changes that can conserve PPE. Donato identifies transmission mitigation equipment to include partitions, face coverings, masks, respirators, and gloves.

Users of NIOSH-approved filtering facepiece respirators (FFRs) in non-healthcare settings should develop and implement strategies to conserve and extend their current stock of respirator supplies while protecting their workers during the COVID-19 pandemic. – CDC

Partitions

For many activities, such as electrical installations, partitions can reduce virus transmission in three ways. They intercept respiratory droplets. Their positioning can help re-enforce physical distancing requirements. And they enhance the effectiveness of face coverings helping to reduce the reliance on masks and respirators while improving worker comfort.

Partition design, use, and maintenance should be carefully planned. Experts suggest choosing dimensions that protect the breathing zone of the tallest person using the partition. Think of the breathing zone as a 2-foot bubble extending out from the face. The partition must be secure and not block or impede emergency egresses. And partitions must be disinfected daily, or when there is a worker change.

Face Coverings As Barriers

Cloth face coverings should be considered as portable barriers. OSHA does not recognize cloth face coverings as appropriate substitutes for PPE. Face coverings do not protect wearers from virus infection. They only aid in limiting the spread when everyone on the jobsite wears them.

Face coverings vary in effectiveness. In a recent study, researchers found that droplets traveled more than 8 feet without a mask; 3 feet, 7 inches with a bandana; 1 foot, 3 inches with a folded cotton handkerchief; 2.5 inches with a stitched quilted cotton mask; and about 8 inches with a cone-style mask.

Donato warns that there are some important safety concerns when using face coverings. First, contractors should determine that cloth face coverings comply with state or local requirements. They must cover the nose and mouth and fit snugly but comfortably against the side of the face, allowing for breathing without restriction, and they should be handled as little as possible. Workers should replace coverings when they become wet, soiled, or otherwise visibly contaminated during the work shift.

Donato warns that the use of face coverings can result in heat-related issues. He recommends contractors refer to the recently updated OSHA guide designed to help employers and worksite supervisors prepare and implement hot weather plans. He also reminds contractors to be mindful of worker hydration needs.

Facemasks

Disposable facemasks are the next level of protective barrier, preventing splashes, sprays, large droplets, or splatter from entering the wearer’s mouth and nose. The protective quality of disposable facemasks varies depending on type of material used. Facemasks are not respirators and do not protect the wearer from breathing in small particles, gases, or chemicals in the air.

Respirators

Respirators, protect wearers from breathing in hazardous contaminants, including viruses. Contractors are familiar with respirators, such as N-95 models, as they are required equipment for some construction activities. There has been a great deal of discussion regarding OSHA rules on respirator use in construction. Donato advises two items regarding respirators. First continue to use respirators as part of your safety program. And second pay close attention to sourcing when purchasing replacements. Donato also urges contractors to regularly refer to the OSHA website for updates to memorandums regarding any updates.

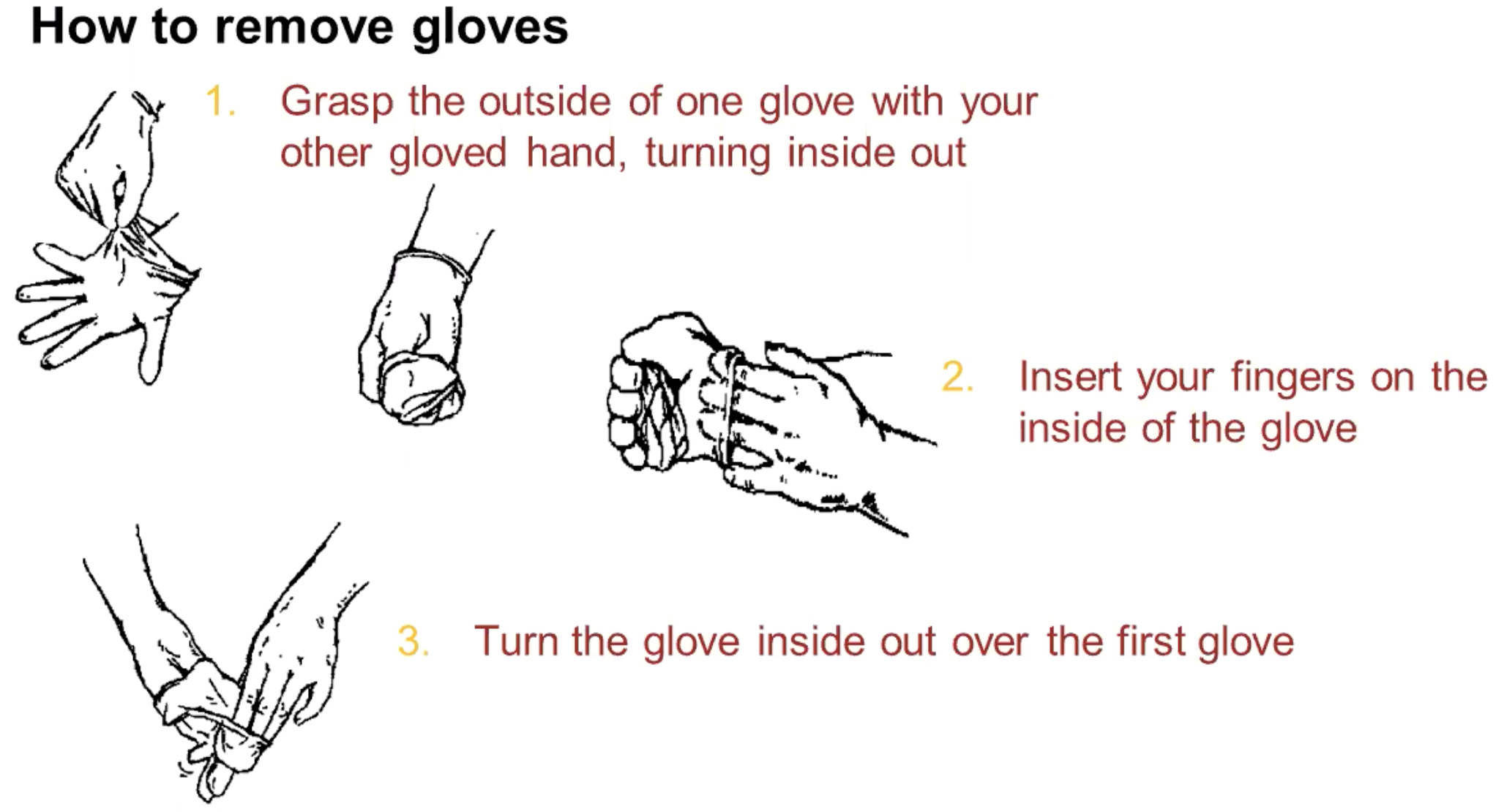

Gloves: The Best Protection From Contact Spread

A construction sites offers many contact points where workers can end up touching areas that could be infected. Proper hygiene procedures such as hand washing and hand sanitizing offer protection. But when working in areas where virus infection is more likely to be highly concentrated such as partitions, common rooms, and touch points, gloves offer greater protection.

Workers should remember that gloves, even after cleaning, can also carry COVID-19. The CDC recommends discarding gloves after each use; wash your hands immediately after removal.

Updating Training

Every contractor’s goal is for a zero near miss and reportable safety and health incident on every jobsite every day. In the midst of a pandemic to achieve these goals requires even greater attention to detail.

Donato urges contractors to include updating PPE training as part of their effort. For most construction workers the use of PPE is not new. Even so, Donato urges contractors to focus on demonstrating how traditional equipment should be properly used and maintained to mitigate virus spread.

He suggests starting simply by reminding workers how to properly use respirators and gloves. Check out these links to OSHAs “How To Wear and Remove a Respirator” https://news.whitecap.com/osha-how-to-properly-wear-and-remove-a-respirator/

And AHSI’s video “How To Remove Gloves”

ASHI Glove Removal Instructions (used with permission)

This video clip is used with the permission of the American Safety and Health Institute (ASHI). Depending on the occupational setting, additional personal pr…

And most importantly, Donato urges that all training goals include the message “PPE is designed to safeguard workers when following physical distancing and using effective disinfection protocols”.

Follow these links to the 4 Steps To A COVID-Free Jobsite:

PLAN • PREPARE • POST • PREVENT

Thank you for this information; found it very usefull